Product Description

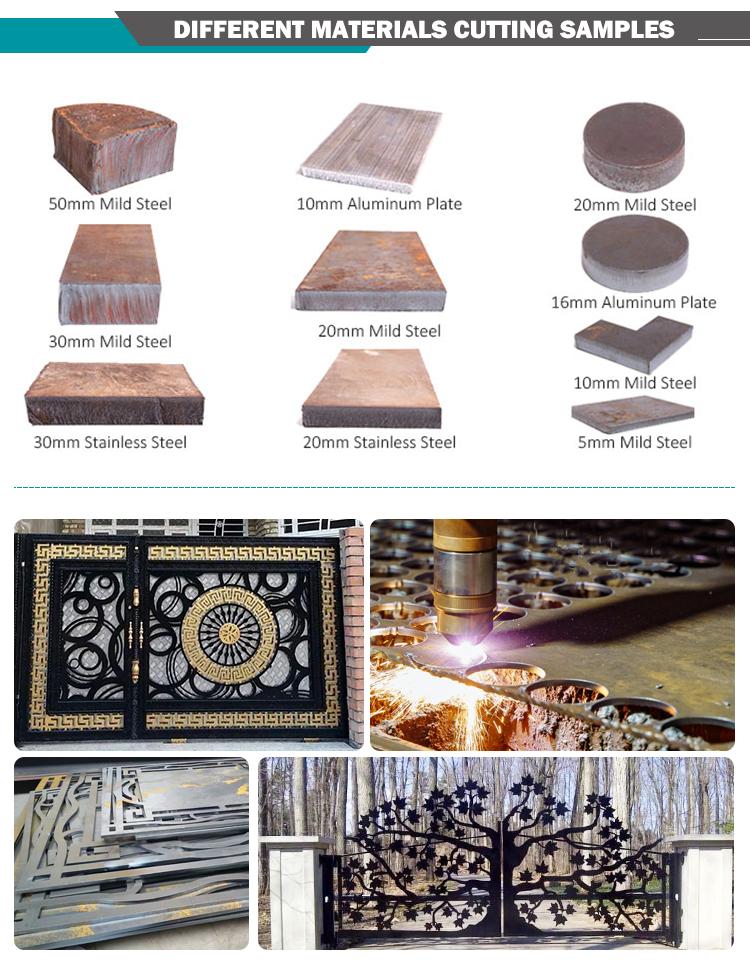

Good Quality Cheap Cnc metal cutting tables

Steel Metal Cnc metal cutting tables is the main machine in industry workshop. Its quality and precision will decide the level of your products directly. Choose a high quality metal cutting tables is important!

We Have Three Type metal cutting tables:

Choice 1-Portable Plasma Cutting Machine-Cheap and Big Function

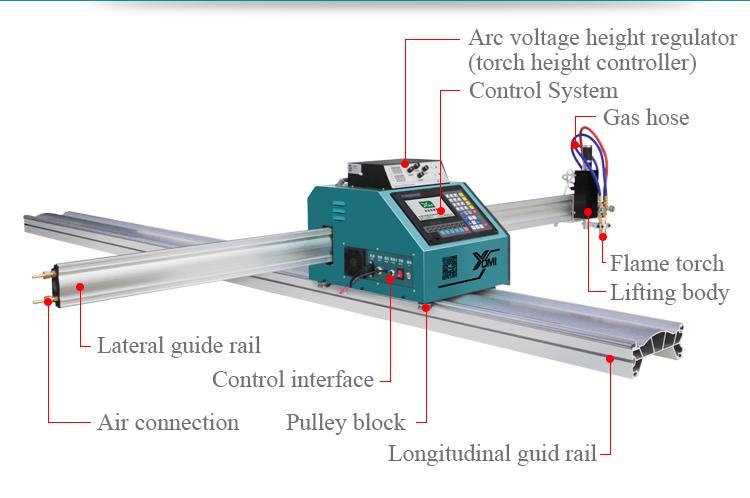

Portable Plasma Cutting Machine is an automatic portable CNC machine with THC. The cutting control system can control the motion of 2 axis, which is suitable for flame or plasma cutting. The THC controller is designed to change the height between torch & workpiece. This kit is accurate,stable, low noise, while easy to operate. With graphic to guide your use, come with 2 booklet of user manual to explicitly guide your operation.

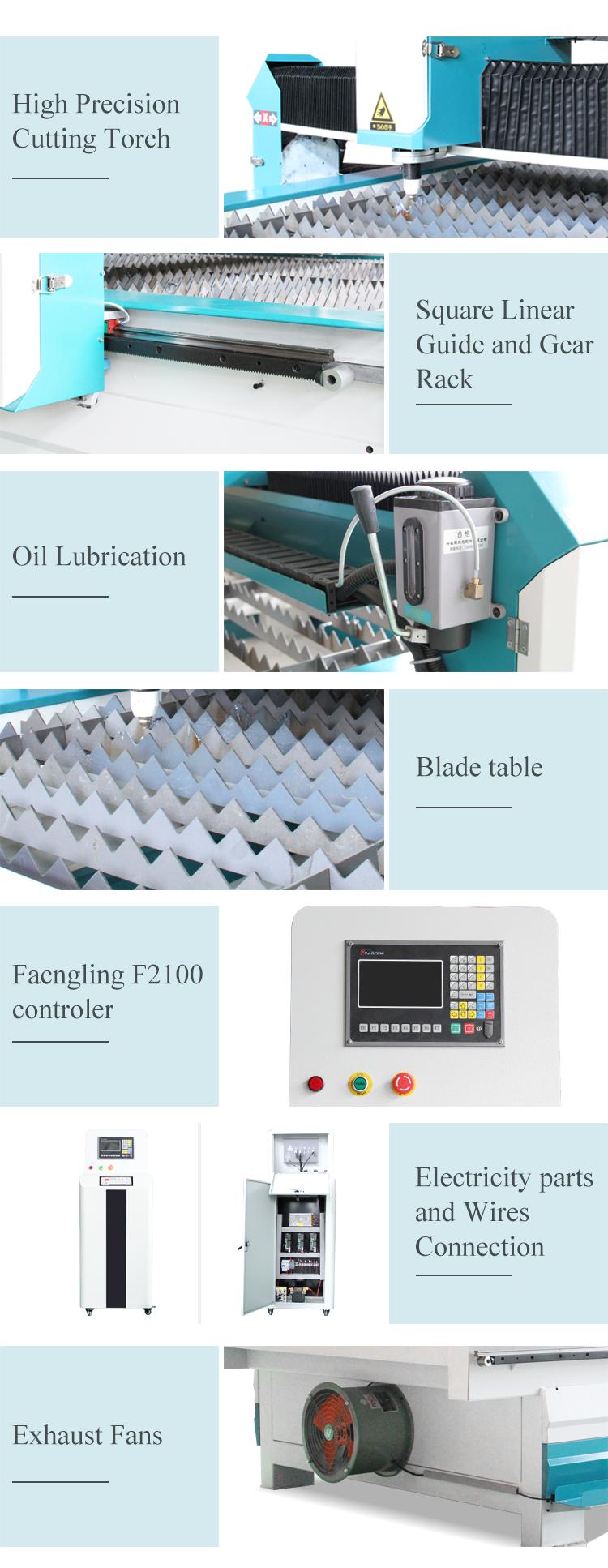

The metal cutting table details show

1. CNC SYSTEM

The metal cutting table Equip with Shanghai Fangling F2100B CNC operating system

humanized design and simple operation The system comes with 48graphic , which can cut directly by inputting plate size.

Using industrial-grade ARM7 processing chip, 7-inch color LCD display.

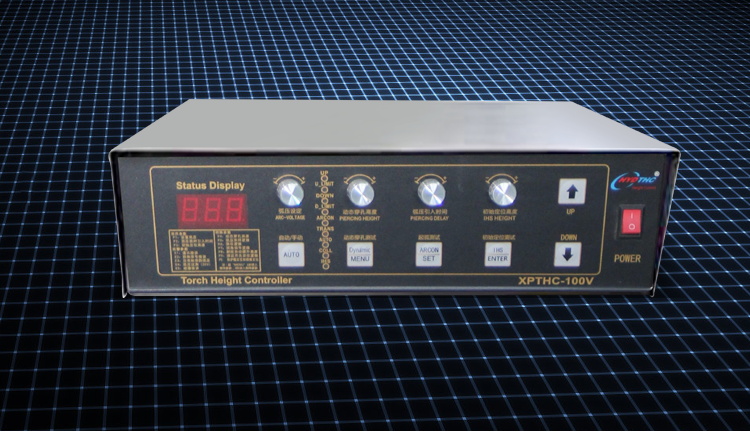

2.TORCH HEIGHT CONTROLLER

The metal cutting table equip with Shanghai Fangling 1621 arc voltage regulator Manual operation function: automatic, manual up and down, initialpositioning test Automatic operation: After cutting program sends out the arc start-ing signal, the arc voltage height regulator automatically completes the initial positioning.

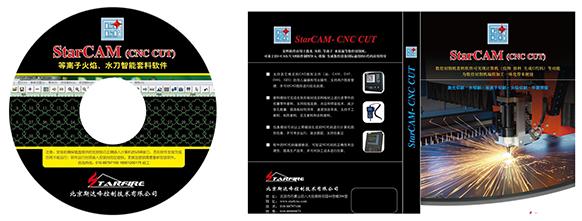

3. STARCAM NESTING SOFTWARE

The metal cutting table Support common edge cutting, short-linecontinuous cutting and bridge cutting.

Support multi-sheet manual matrix nesting, scheme nesting, combi-nation nesting, automatic nesting and common edge nesting. Support automatic lead-in and lead- out joining and lead movement.

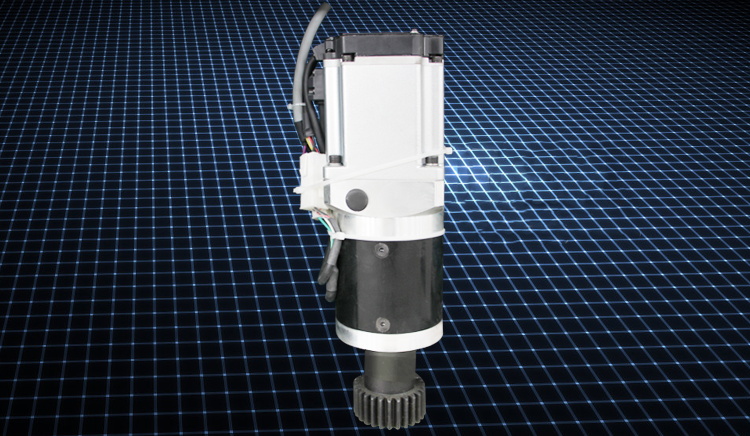

4.LIFTING BODY

The metal cutting table Adopt T YHE penmanent magnet DC planetary gear motor. Cast aluminum structure, light material, not easy to deform. Equipped with upper and lower limit switches to prevent damage to the components caused by operating errors. Plasma positioning adopts micro switch, with low failure rate.

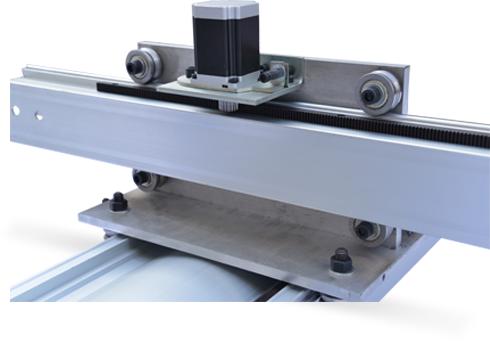

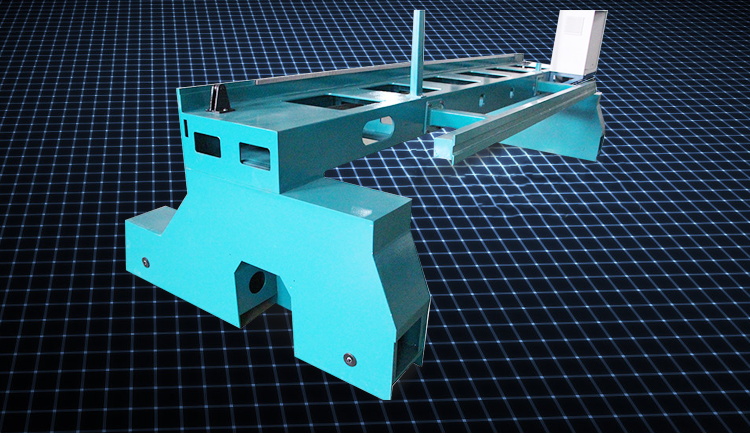

5.MECHANICAL STRUCTURE

The metal cutting table’s bottom plate of beam uses bearing pulley block, 4 pcs V39 bear-ings to bear the force. Ensure the machine moves stable and service life long.

The metal cutting table Parameters

| No. | Items | Parameters |

| 1 | Machine Voltage | Singal phase220V,50HZ |

| Plasma power Voltage | Three Phase 380V,50HZ | |

| 2 | Cutting mode | Plasma+Flame |

| 3 | Effective cutting range(mm) | 1500mm×3000mm or customized |

| 4 | Cutting speed(mm/min) | 50-3500mm/min |

| 5 | Plasma power | Huayuan or Yomi LGK-120A/200A/300A or Hyperthem 80A/105A/125A |

| 6 | Plasma cutting thickness | According to power source models |

| 7 | Moving precision | ±0.2mm/m |

| 8 | Cutting system | Fangling F2100B |

| 9 | THC | Fangling F1620 |

| 10 | Software | ProNest8(standard) or Starcam |

| 11 | Total weight(kg) | 126KGS |

| 12 | Emergency stop | Yes |

| 13 | Working temperature | -5~45℃ |

| 14 | Relative humidity | <95% No condensin |

Choice 2-Table Type Plasma Cutting Machine

Table type plasma cutting machine is in high automation and efficiency,easy operation and long service time. The plasma cutting machine is table structure with double-driven system, working size can be customized upon requirement. It can be used for cutting carbon steel, stainless steel and non-ferrous metal in any 2D graphics,this is widely used in metal cutting fields.

The metal cutting table Parameters

| Machine working size | 1500mmX3000mm |

| Machine structure | Tube Welding structure |

| Control system | Fangling F2100 controller |

| Transmission | Square Linear guide and gear rack |

| Motor and driving system | Stepper motor with reducer |

| Thc system | Shanghai Fanling F1621 THC |

| Working Table | Blade industry working table |

| Cutting torch | High precision Plasma cutting torch |

| Power source choosing | Yomi Brand and Hypertherm Power source for option |

| Power source power | 60A,100A,120A,160A,200A,300A,400A for option |

| Material cutting | Carbon Steel,Stainless Steel,Aluminum,Galvanized |

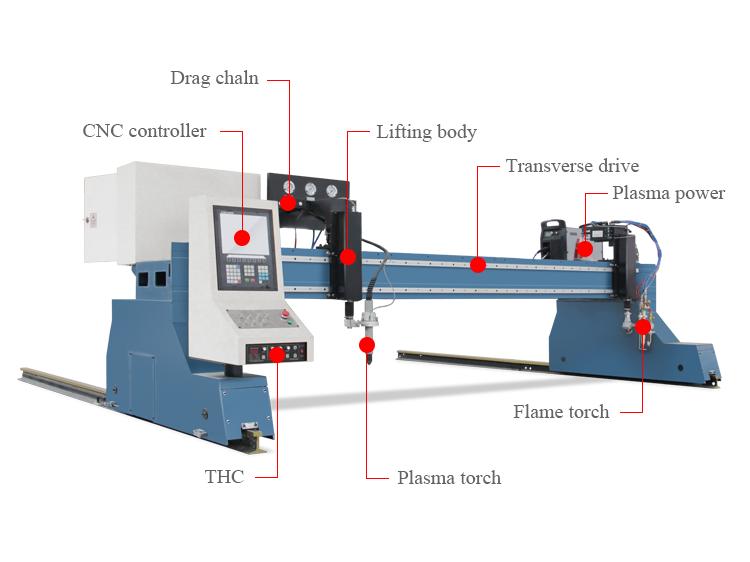

Choice 3-Gantry Type CNC Plasma Cutting Machine

Gantry type CNC plasma cutter is in high automation and efficiency,easy operation and long service time. With double-driven system, working size can be customized upon requirement. It can be used for cutting carbon steel, stainless steel and non-ferrous metal in any 2D graphics,this is widely used in metal cutting fields.

The metal cutting table DetailsGood rigidity, high transmission accuracy

The metal cutting table’s frame beam is one-time milled by large gantry milling machine to ensure cutting accuracy. The hollow welding process is convenient for heat dissipation, it make sure stable operation and high cutting accuracy.

Graphic programming

The metal cutting table can carry out all kinds of complex graphics proofing and mass production,eliminating the need for complex punch molds, saving proofing time and reducing costs.

The metal cutting table Longer life and lower failure rate

Arc voltage adjustment has high control accuracy, stable performance, stronganti-interference ability, and prevents gun collision.

The metal cutting table High transmission accuracy

The use of backlash-free soft fit device can effectively reduce gear engagement error,and can also prevent iron filings from entering the gear and causing excessive wear on machine when equipment is running.

The metal cutting table Parameter

| Standard type | 4*10m Effective cutting area:3.15m*8m |

| Cutting method | Flame/ Plasma |

| Cutting Thickness | Flame:6-60mm; Plasma:1-25mm |

| Cutting length | Can be customized |

| Cutting speed | Flame 20-700mm/Min Plasma 500-3500mm/min |

| Cutting width | 3m,can be customized |

| Plasma torch anti-collision protection system | Yes |

| Driving method | Servo |

| Cutting length accuracy | ±1.0mm |

After Sales Service

After Sales Service 1. One year warranty for whole machine 2. We have experienced after-sales service team,we can send installation video or file to customers and guid installation for easy operated machines and we can also arrange our engineers to visit customer's site for installation and training for complicated machines. 3. Full stock of spare parts and consumables are at competitive price.

FAQ

1. Can I have a cutting sample? Yes, after getting your drawings,we can do cutting sample for you. 2. Can you supply OEM Service? Yes, we can supply OEM service. 3.What is the available shipping way? Nude Packed in 20ft container. 4 What is deliver time? We will delivery the goods within 7-15 work days after received payment. 5. What is your payment term? We can accept T/T,Western Union,L/C,Aliexpress Escrow, Credit Card.