1.We are the first one develop the square tube cutting and beveling machine supplier in china.

2.Our control system together with Taiwan Advantech Industrial Computer.

3.Easy to operate, modeling making is easy , only need from software through the centerline, easily create pipe, arc tube, square tube, rectangular tube, angle, channel, H-beam and other components . Training time is short , only need input wall thickness , bevel angle , threading length on the software , it can cut directly with the graphics in the gallery.

4.Software with better compatibility , support TEKLA,3D ,3S, STCAD and AutoCAD .

5.twist angle support.

6.Support API ,small angle cutting.

7. No need secondary making the model , can input the the model into software one time,directly form the whole project budget chart of the materials . 8. Optimization nesting . 1)Support twist angle nesting 2)support remaining materials secondary nesting 9. After nesting can be batched into G code .Each pipe only need 3 seconds transfer into G code . 10. With Rich graphics database ,free offer to the customer 11.3D Modeling cutting track can spread out to see in a real time ,easy to know the process 11. Support continuous cutting,with high cutting efficiency . 12. 13. Our software can enjoy lifetime updates for free.

7. No need secondary making the model , can input the the model into software one time,directly form the whole project budget chart of the materials . 8. Optimization nesting . 1)Support twist angle nesting 2)support remaining materials secondary nesting 9. After nesting can be batched into G code .Each pipe only need 3 seconds transfer into G code . 10. With Rich graphics database ,free offer to the customer 11.3D Modeling cutting track can spread out to see in a real time ,easy to know the process 11. Support continuous cutting,with high cutting efficiency . 12. 13. Our software can enjoy lifetime updates for free.(4), pipe locking With adjustable third claw automatic centering chuck locking pipe diameter.

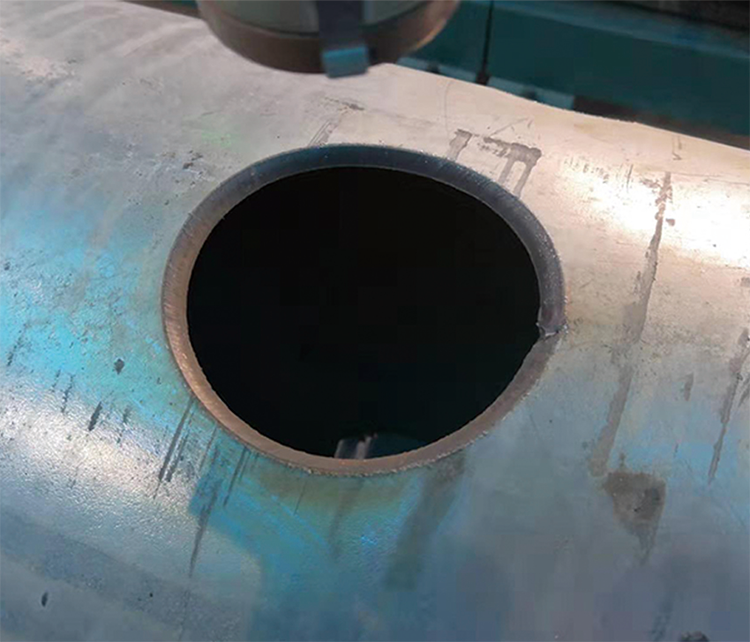

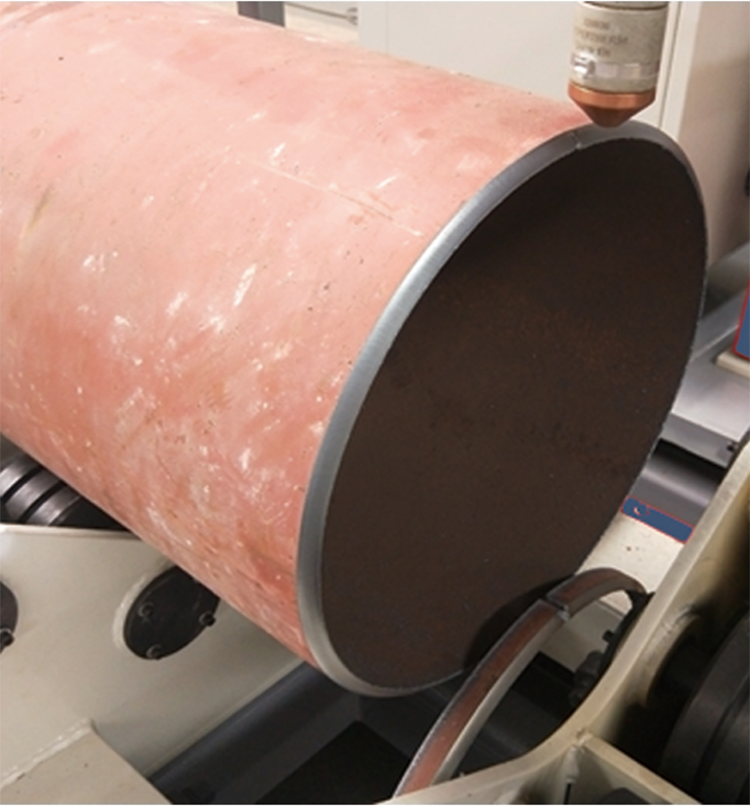

(5), the open cut Move the cutting head to the tube cutting, automatic positioning device automatically according to the procedure under a cut, to complete the cutting process and according to the programming.

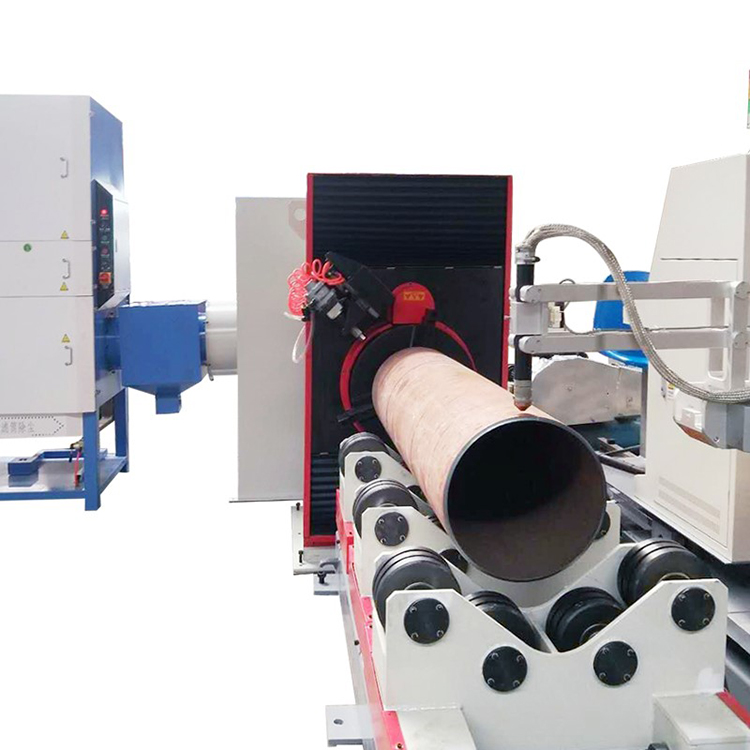

| Round pipe diameter | 108~1000mm 219~1210mm |

| Cutting length : | 6000mm 9000mm 1200mm |

| Cutting methed | plasma and flame(oxy-fuel) |

| Cutting speed | 10~2000mm/min |

| Travelling speed | 10~6000mm/min |

| Plasma power brand | Hyperthem/ Kjillbery/Huayuan |

| Driving method | Japan Panasonid Servo motor |

| Control system | Adcancetch IPC with Yomi PIP |

| Programing software | Curve library, Tekla, AuotoCAD |

| Cutting length accuracy | ±1.5mm |

| The axial swing angle of the cutting torch | α=±60° |

| The radial swing angle of the cutting torch | β=±55° |

| Oblique crossing angel | 15°~170° |

| Angle error | ±1° |

| Bevel angle | plasma≦±45° flame≦±55° |

1. One year warranty for whole machine 2. We have experienced after-sales service team,we can send installation video or file to customers and guid installation for easy operated machines and we can also arrange our engineers to visit customer's site for installation and training for complicated machines. 3. Full stock of spare parts and consumables are at competitive price.

1. What kinds of after-sales service can your company supply? One year's warranty for whole welding machine. We will send spare parts for free during warranty period. About main board, we can supply life long service.

2. Can you supply OEM Service? Yes, we can supply OEM service.

3. What is deliver time? We will delivery the goods within 15-20 work days after received payment.

4. What is your payment term? We can accept T/T,Western Union,L/C,Aliexpress Escrow, Credit Card.

Material :Workpiece materials apply range: Mild steel( stainless steel,copper andnickel pipes,cut by plasma) Type :round pipe Industry :Widely used in water/chemical oil&gas pipeline industries, marine engineering, offshore buildings,boiler&vessels,heat exchangers,etc.

(1) , programming Programming can be directly on the machine or offline editor. Using input cutting parameter selection menu type, such as outside diameter, wall thickness, bevel Angle, deviation, compensation data, and so on. At the same time a seamless connection can be made by other professional software such as STCAD.

(2), loading and unloading of workpiece Operator initiator on the machine, the pipe placed in the tray by hoisting tools.

(3), measurement level Operators according to pipe diameter deviation with a header hand lever level adjustment.