Introduction:

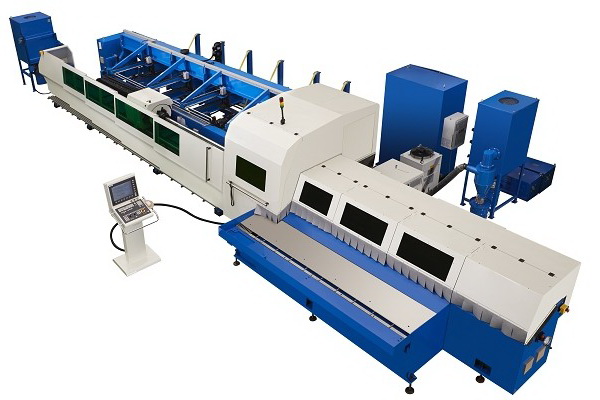

In today's fast-paced manufacturing world, the demand for advanced cutting technologies is ever-increasing. Enter the game-changing 1000W Fiber Laser Metal Cutting Machine for Square Tube – a powerful and versatile CNC Square Cutting Machine that ensures impeccable metal sheet and pipe cutting with unmatched precision, speed, and efficiency. In this blog post, we will delve into the remarkable features of this cutting-edge CNC machine, highlighting its superior performance and the benefits it offers to various industries.

1. Unveiling the Power of the 1000W Fiber Laser Metal Cutting Machine:

The 1000W Fiber Laser Metal Cutting Machine is a state-of-the-art solution that combines technology and innovation to deliver exceptional results. Equipped with a high-power 1000W fiber laser, this machine boasts incredible cutting capabilities for a range of materials, particularly steel square tubes. With its precise beam delivery system, it ensures clean, accurate, and burr-free cuts every time, revolutionizing the metal cutting process.

2. A Comprehensive Solution for Metal Sheet and Pipe Cutting:

Unlike traditional cutting machines that only specialize in one aspect, the 1000W Fiber Laser Metal Cutting Machine offers the convenience of tackling both metal sheets and pipes. By eliminating the need for separate machines, this integrated solution enhances productivity and reduces operational costs, making it an invaluable asset for metal fabrication industries. The CNC Square Cutting Machine effortlessly handles square tubes and metal sheets of various thicknesses, enabling diverse applications with unparalleled speed and accuracy.

3. Unmatched Precision for Intricate Designs:

Precision is the key to success in the manufacturing industry, and the 1000W Fiber Laser Metal Cutting Machine encompasses this aspect flawlessly. Powered by advanced CNC technology, this machine allows for the creation of intricate designs with intricate cuts, slots, and contours. The accuracy of the laser beam ensures that even the most complex patterns are executed flawlessly, guaranteeing high-quality end products and customer satisfaction.

4. Boosting Efficiency with High-Speed Cutting:

Time is money, and the 1000W Fiber Laser Metal Cutting Machine understands that. With its high-speed cutting capabilities, it significantly reduces production time and boosts overall efficiency. The cutting speed is optimized to ensure swift and accurate operation, enabling businesses to meet tight deadlines while maintaining superior quality standards. This laser cutting machine is a game-changer for industries that demand both speed and precision.

5. Safety Features and User-Friendly Interface:

Apart from its cutting capabilities and exceptional performance, the 1000W Fiber Laser Metal Cutting Machine prioritizes safety and ease of use. It is equipped with advanced safety features, including sensors that automatically shut down the machine in case of any discrepancies. Additionally, the intuitive user interface makes it easy for operators to navigate through the machine's functions, allowing for customizations and adjustments as per specific requirements.

Conclusion:

The 1000W Fiber Laser Metal Cutting Machine for Square Tube is reshaping the metal fabrication industry by combining the power of fiber laser technology, precision cutting, and versatility. Its ability to effortlessly handle metal sheets and square tubes has revolutionized the production process, maximizing efficiency and minimizing costs. Boost your manufacturing capabilities with this remarkable CNC Square Cutting Machine and experience an entirely new level of productivity, speed, and exceptional quality. Embrace the future of metal cutting today!