Their three highly efficient cutting systems include plasma, waterjet, and laser cutting mechanisms, each possessing an impressive arsenal of accessories and consumables working painlessly alongside sophisticated software to achieve highly precise cuts.

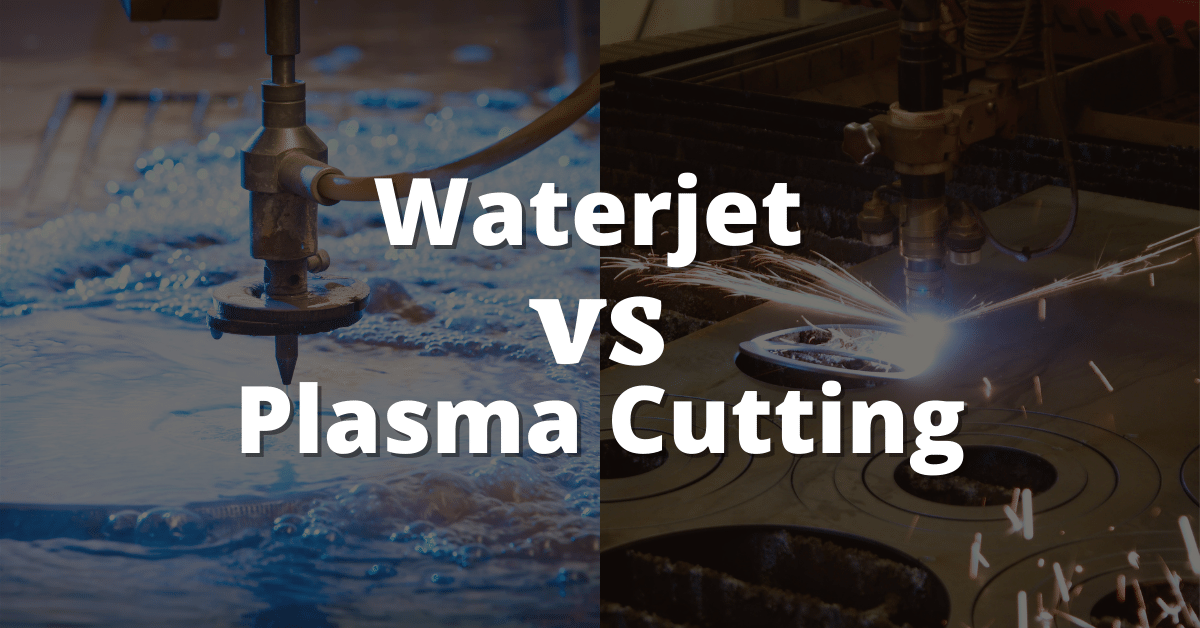

Hypertherm plasma cutting systems are some of the most advanced in the industry. They use a plasma torch to cut through a variety of conductive metals, offering highly precise cuts with limited shaping and dross waste. But it’s the range of Hypertherm Plasma Accessories which offer its true potential. Accessories include everything from consumable parts like nozzles, electrodes, and shield caps to various torches and mounting hardware to improve cutting capabilities.

Waterjet cutting uses pressurized streams of water to slice through a wide variety of materials, from hard metals to fragile glass. Hypertherm’s waterjet products feature the proprietary Intensifier technology for a streamlined and efficient cutting process. Accessories include abrasive delivery systems, water filtration options, and pump parts for optimal performance.

Laser cutting has become a standard in precise fabrication processes. Hypertherm’s line of laser cutting systems couples high power with accuracy and flexibility, capable of cutting through a variety of materials. Accessories for these devices include cutting heads, couplers, ceramic rings, focusing lenses, and cooling accessories.

Aside from their advanced cutting systems, Hypertherm also offers software that works alongside its hardware to provide accurate cutting and fabrication designs. Their ProNest software is a popular example of such technology, improving the nesting process to save users both time and money. Introducing progress in job management and a host of features to optimize cutting speeds.

Bottom Line

When it comes to precision cutting, selecting the right machine is crucial. Hypertherm’s plasma, waterjet, and laser cutting systems offer the perfect balance of accuracy and speed, combined with user-friendly software and a wide range of accessories. These products are economical, efficient, and come with the peace of mind of having support options available globally. Their suite of accessories, including consumables, torches, and cutting parts, allows each cutting system unparalleled versatility, ensuring the user can complete every project with ease. When looking for a solution that can handle even critical cutting tasks, Hypertherm is a brand that you can trust.