In the metal processing industry, precision and efficiency are two critical factors that can make or break a project. Hence, the demand for advanced technologies such as metal tube laser cutting machines is increasing. These machines offer a precise and quick way to cut and shape metal pipes and tubes, reducing production costs and improving product quality. In this blog post, we will discuss the benefits, applications, and features of metal tube laser cutting machines.

What is a Metal Tube Laser Cutting Machine?

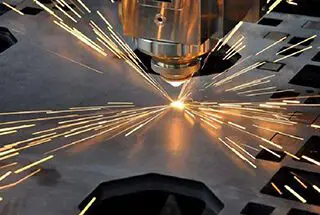

A metal tube laser cutting machine is a type of laser cutting system that uses a laser beam to cut metal pipes and tubes with high precision. The laser beam generated by the machine is focused on the material to melt or vaporize it, creating a cut with a smooth and clean edge. This method of cutting is quicker and more precise than traditional cutting methods such as sawing or milling.

Benefits of Metal Tube Laser Cutting Machines

There are several advantages to using a metal tube laser cutting machine, including:

1. Precision: Metal tube laser cutting machines offer unparalleled precision, accuracy, and repeatability. Because of this, they can produce complex shapes and cuts, including angled cuts and beveled edges.

2. Speed: Laser cutting machines can cut metal pipes and tubes at high speeds, reducing production time and increasing output.

3. Versatility: Metal tube laser cutting machines can work with a wide range of materials, from stainless steel to aluminum and brass, making them ideal for a range of applications.

4. Efficiency: Laser cutting machines have a low heat affected zone (HAZ), which means they can cut and shape materials without degrading or warping them. This reduces the need for additional processing or finishing, saving time and reducing costs.

Applications of Metal Tube Laser Cutting Machines

Metal tube laser cutting machines have many applications in various industries, including:

1. Automotive: Laser cutting machines are used to cut and shape exhaust systems, chassis components, and other metal parts.

2. Aerospace: These machines are used to cut and shape sheet metal, tubing, and other components used in aircraft construction.

3. Construction: Laser cutting machines are used to cut and shape metal pipes and tubes used in construction projects.

4. Furniture: Metal tube laser cutting machines are used to cut and shape metal furniture components, such as chair legs and frames.

Features of Metal Tube Laser Cutting Machines

When selecting a metal tube laser cutting machine, it's important to consider the following features:

1. Laser source: There are several types of laser sources, including CO2, fiber, and diode lasers. Each type has its own advantages and disadvantages, so it's essential to choose the one that best fits your needs.

2. Power: Power is an essential factor in determining the cutting speed and thickness of the material that can be cut. Higher power lasers can cut thicker materials at higher speeds than lower power lasers.

3. Cutting area: Cutting area refers to the size of the machine's cutting bed. It's essential to choose a machine with a large enough cutting area to accommodate the size of the pipes and tubes that need to be cut.

4. Control system: The control system is responsible for controlling the laser's movement and power during the cutting process. An advanced control system can improve cutting accuracy and efficiency.

Conclusion

Metal tube laser cutting machines are the future of metal processing, with their unmatched precision, speed, and efficiency. These machines have a range of applications in various industries, including automotive, aerospace, construction, and furniture. When selecting a metal tube laser cutting machine, it's essential to consider many factors such as laser source, power, cutting area, and control system. By investing in a metal tube laser cutting machine, businesses can increase productivity, reduce costs, and improve product quality.