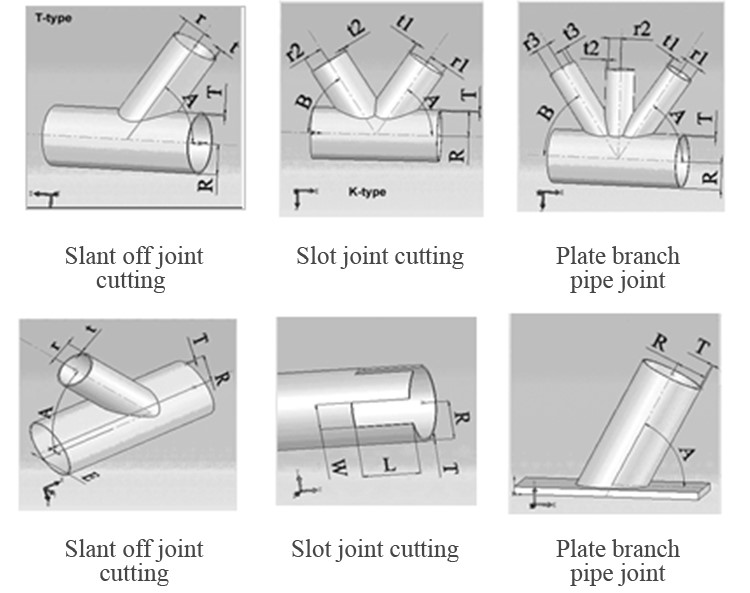

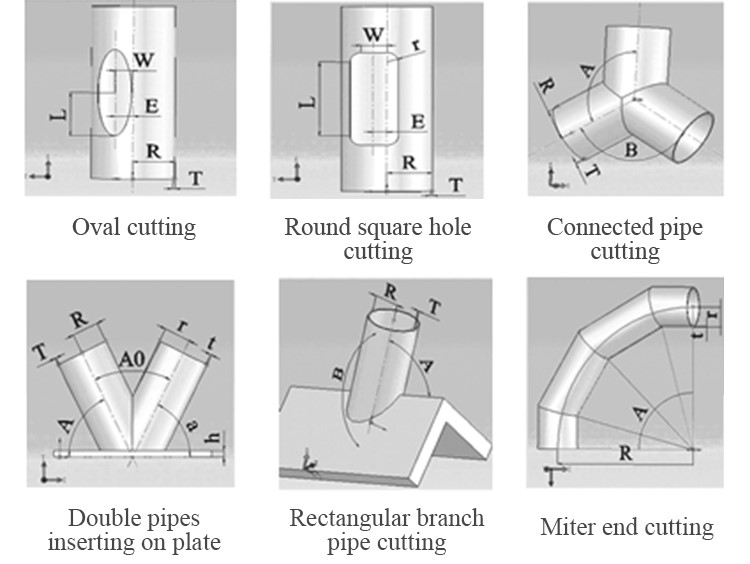

| Model | 5 axis pipe CNC plasma cutting machine |

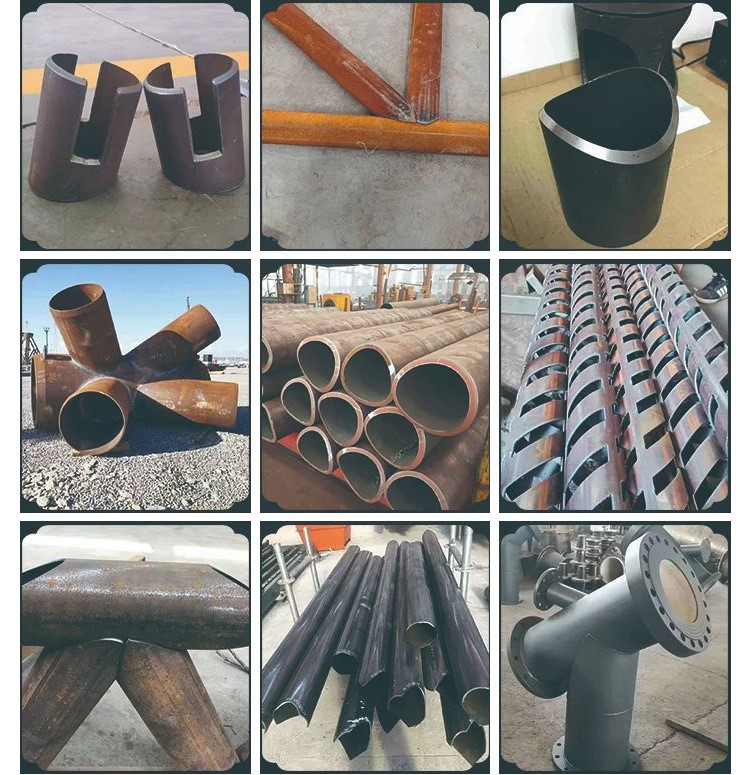

| Pipe Diameter | 60-630/800mm ,cutting length 6000/9000/12000mm |

| Cutting method | Plasma & flame |

| Plasma power | Hypertherm 125A plasma power , For 1-25mm |

| Flame cutting thickness | 6-60mm |

| Plasma cutting speed | 10-2000mm/min |

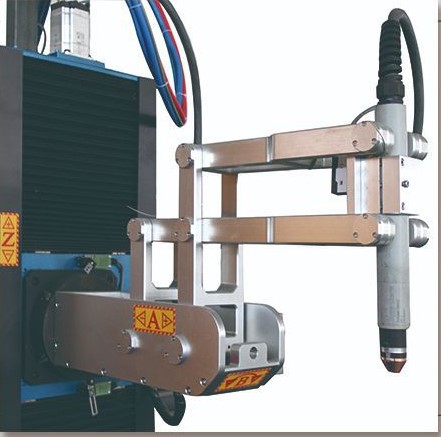

| A axis Bevel angle | ±45 degree |

| B axis Bevel angle | ±45 degree |

| Plasma bevel thickness | 5-14mm |

| Flame bevel thickness | 6-40mm |

| Computer | Taiwan Advantech Industrial Computer |

| Driving motor | Japanese Panasonic Servo motor with reducer |

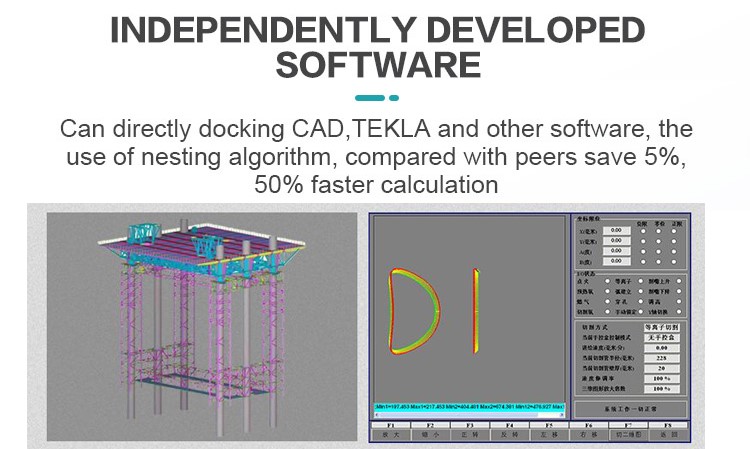

| Software | Pipe Nest software |

| Load | 5000kg |

| Weight | 7000kg |

| Shipping | 40ft container |

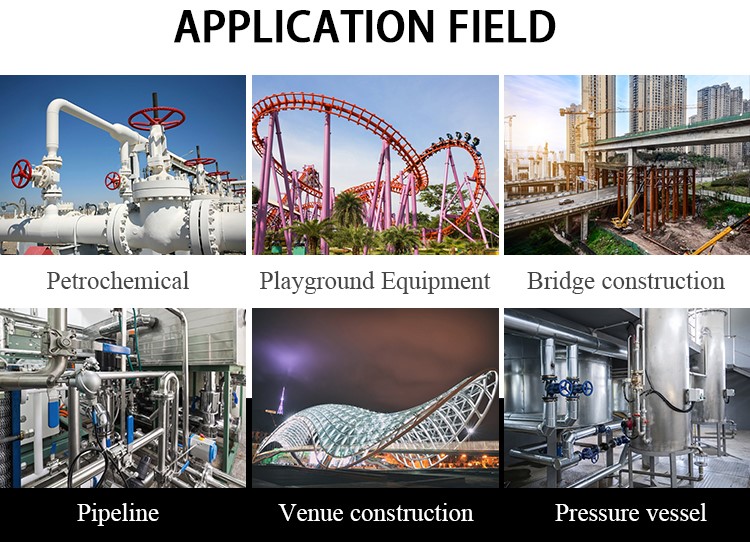

Shandong Yomi Intelligent Science and technology Co., Ltd is an Industrial Leader in the Cutting & Welding Field. We target to build the Integrated Supply Chain with High Quality Products at Competitive Prices and offer a complete After-Sales Service in the Local Market. We cater for all Steel Fabricators, Heavy Equipment Manufacturers as well as Small Workshops and Engineering Companies, etc. We have established overseas warehouses in South Africa. This is our first overseas warehouse. More warehouses will be established around the world. In addition to the warehouse, it is also equipped with local after-sales service personnel who have been trained in our factory. Inventory products + local services + integrated supply chain will be our main business method.

Shandong Yomi Intelligent Science and technology Co., Ltd is an Industrial Leader in the Cutting & Welding Field. We target to build the Integrated Supply Chain with High Quality Products at Competitive Prices and offer a complete After-Sales Service in the Local Market. We cater for all Steel Fabricators, Heavy Equipment Manufacturers as well as Small Workshops and Engineering Companies, etc. We have established overseas warehouses in South Africa. This is our first overseas warehouse. More warehouses will be established around the world. In addition to the warehouse, it is also equipped with local after-sales service personnel who have been trained in our factory. Inventory products + local services + integrated supply chain will be our main business method.

1.Are you factory or foreign trade company?

We are factory ,do both domestic and foreign market

2.What shall we do if don't know how to operate your machine after bought from you?

We have detailed installation and operating instructions attached, also comes with video, it is very simple. We have telephone and email support at 24 hours a day. If you need our engineer go to your factory installation and training , that all no problems

3.What's the quality of your products?

For the machine frame all made by ourselves, quality and delivery time have enough guarantee . Also our products passed CE certification, exported to lots countries around the world, such as Russia, Iraq, Belgium, Kazakhstan, Korea, etc. You can rest assured with the quality absolutely.

4.What to do if the machine has a problem?

24 hours timely response of mail and phone calls. If the parts broken belong to non-artificial factors within 12 months, we offer free replacement. If beyond 12 months, customers should bear the freight back and forth and accessories cost.

5.What other things also need after we bought your machines?

(1) With flame cutting: you just need to access to oxygen and fuel gas.

(2) With plasma cutting: need plasma power source and air compressor. You can match plasma power supply by yourself, or buy together with the cutter from us, it's optional. If you buy from us, we will connect the wires of plasma power source and CNC cutting machine together, then more conveniently to use.

6.What's the leading time after payment?

The leading time is according to your ordered products and quantity.Gantry cutting machine need 15 days ;pipe cutting machine need 30 days ;h beam cutting machine need 60 days .It should be confirmed by the communication with our sales staff.

7.What are your payment terms?

We support T/T, L/C, Western Union and so on. Other ways can also be received after we both sides discussion and agreement

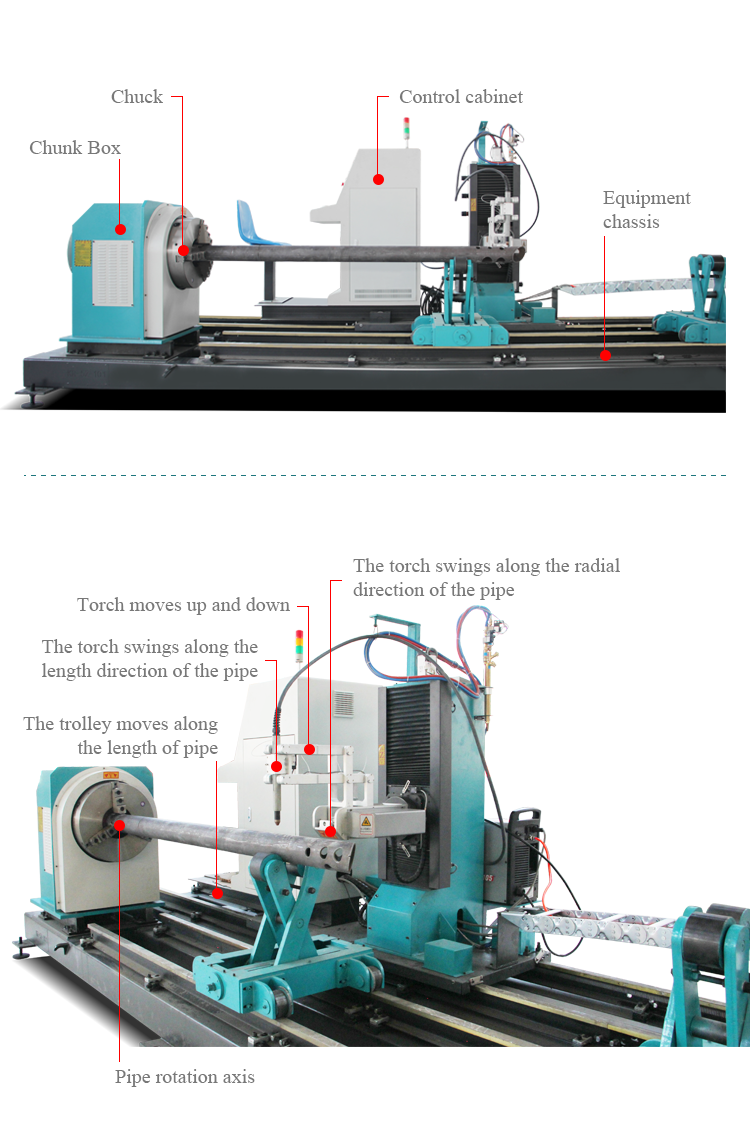

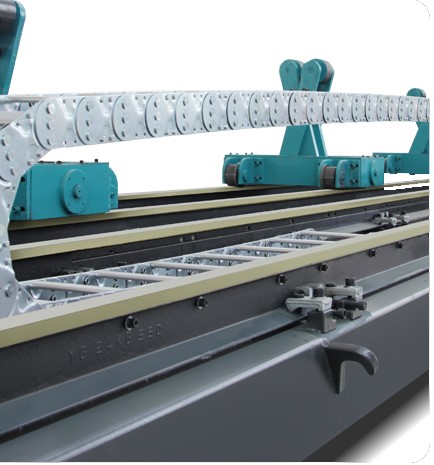

Adopt Japanese Panasonic servo motor drive system, synchronous dual drive. Effectively ensure high cutting speed, high precision and high stability.

The top surface and two side surfaces are precisely processed by a CNC grinder using 24KG grade S5Q ground rails to ensure the leveland parallelism of the moving torch.

The segmented design of the bed can be customized and lengthened according to user's processing requirements. It is convenient to disassemble and put into production quickly, conveniently and efficiently

Automatic centering reduces loading and unloading time.Improve production efficiency.

Pneumatic clamping, clamping force is large and constant. Large and thick tube is not loose and slip

Cutting arm adopts aeronautical aluminum material,resistant to high temperature and pressure,high precision of hole cutting