Oxyfuel Cutting Machine Applied Material :Carbon steel, Stainless steel and other alloys.steel plate and metal sheet Oxyfuel Cutting Machine Manufacturer Mode : Cut off, hole drilling, slotting. Oxyfuel Cutting Machine suitable for Industry :Especially for steel structure construction, shipbuilding, and other metal processing industries

Oxyfuel Cutting Machine Details

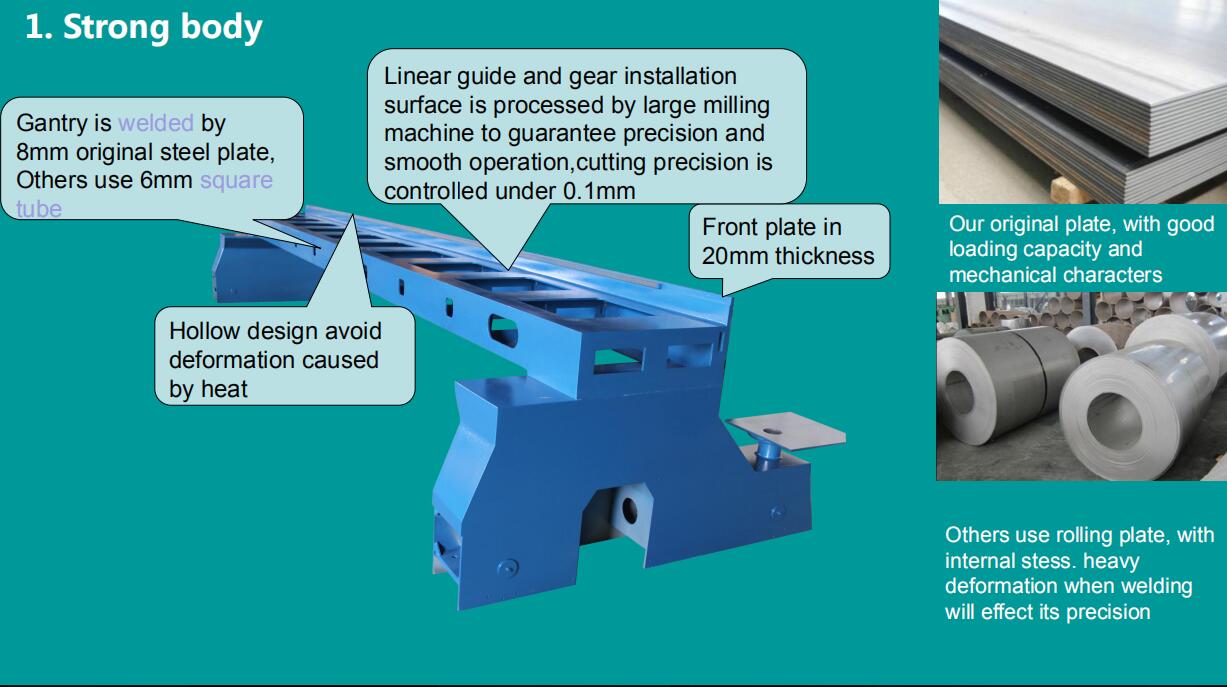

Machine frame Front Beam 8mm thick steel welded ,strong structure 20mm thickness front beam , after one time large gantry milling

Mobile body Hollow design

Mobile body adopts concentric eccentric wheel Adopt hollow design , good heat dissipation ,

tightening structure, stable operation increase the structural strength

Plasma torch collision device

360 °anti-collision mechanism, the use of sensor control,once the plasma torch being hit in any direction,the machine immediately stops moving

Longitudinal drive control system

Portrait of a bilateral gear rack gear drive, coupled with high-precision gear, coupled with the speed and position feedback

Oxyfuel Cutting Machine Paramenters

| Standard type | 4*14m Effective cutting area:3.15m*12m other sizes can be available |

| Cutting method | Flame/ Plasma |

| Cutting Thickness | Flame:6-60mm; Plasma:1-25mm (depend on plasma source you choose) |

| Cutting length | Can be customized |

| Cutting speed | Flame 20-700mm/Min Plasma 500-3500mm/min |

| Cutting width | 3m,can be customized |

| Plasma torch anti-collision protection system | Yes |

| Driving method | Servo |

| Cutting length accuracy | ±1.0mm |

Oxyfuel Cutting Machine Advantages

Why choose our high cutting precision Oxyfuel Cutting Machine?

Raw materials Characteristics

YOMI use original flat plate,with strict size and thickness, high flatness, good loading capacity and mechanical characters. Other brand machine use rolled steel plate, with metal processing, its flatness, inner stress distribution , loading capacity will be worse than original steel plate, or some use square tube, the rust inside of tube can not be removed. Loading capacity is inferior than welding structure

Materials thickness YOMI use 8mm original steel plate welded frame structure.Linear guide running plate in 20mm thick plate. Other brand machine are only 6mm, linear guide running plate in 15mm thickness.

Machining precision YOMI own large gantry milling machine, ensure each machine frame is machined on the machining center Other brand machines are machined by planing machine or no machining

Surface processing YOMI has large sand blastering room and powder coating room. Sand blaster can not only remove the rust on the frame surface, but also remove the inner stress during welding, to ensure the machine precision in long time operation.Powder coating technology is can keep the painting new and firm for many years Other brand machines-No surface processing, simple painting

Oxyfuel Cutting Machine Customer Photos

1. One year warranty for whole Oxyfuel Cutting Machine 2. We have experienced after-sales service team,we can send installation video or file to customers and guid installation for easy operated machines and we can also arrange our engineers to visit customer's site for installation and training for complicated machines. 3. Full stock of spare parts and consumables are at competitive price for Oxyfuel Cutting Machine.

FAQ

Q1. Are you a Manufacturer or a trading company? A1.We are the manufacturer, integrating with design, machining and assembling for Oxyfuel Cutting Machines. Q2. Do you have stock Oxyfuel Cutting Machine ready to deliver? A2. In order to satisfy with the customer for fast delivery, we have certain amount of machines in stock, you can check the machine on LIVE-DEMONSTRATION at any time. Q3. How do you deliver the finished Oxyfuel Cutting Machine? A3. The Oxyfuel Cutting Machine is mostly delivery by sea, rail way or road for some exception. For some urgent part or shipping document we delivered by air or Express like TNT, FEDEX,DHL,UPS,EMS, Etc. Q4. How can you guarantee the after-sales service for Oxyfuel Cutting Machine? A4. We have the special after-sales service department, they will provide training program for operation and trouble shouting during installation. And they will visit the customer regularly for service.all questions will be answered within 3 hours and 90% problem will be solved within 24 hours. Q5. What's delivery time for the Oxyfuel Cutting Machine. A5. Within 20 days after payment. Q6. How can you guarantee your finished Oxyfuel Cutting Machine quality? A6. First, the machine will have 8 hours idle running; Second, we will test the Oxyfuel Cutting Machine with the material working together.

Company Profile

YOMI is professional on CNC cutting machine powered by plasma and oxy-fuel. From basic plate cutting machine, Gantry cnc plasma cutting machine, table cnc plasma cutting machine and portable cnc plasma cutting machine, YOMI is also Leading manufacturer in pipe and profile cutting machine, from pipe cutting and beveling, tube cutting and beveling, beam/angle steel/ channel steel/flat buld processing. By developing our own system and software in 3D profiling, YOMI become the top brand in metal cutting with competitive price and professional products.