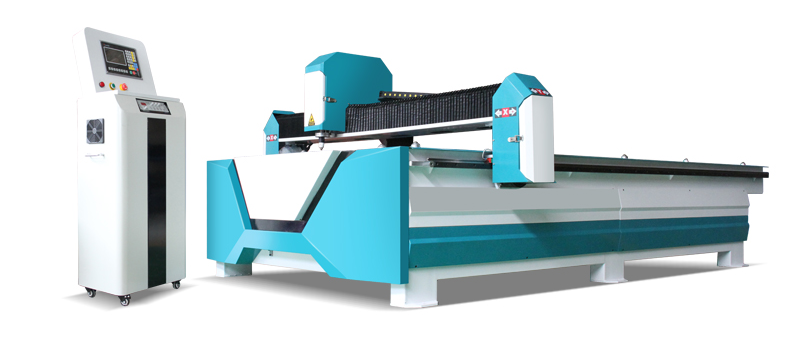

(The photo is just for reference)

2. The Plasma Cnc Machine Technical Parameters

| No. | Project indicators | Technical parameter |

| 1 | Model | YMT-1530 |

| 2 | Horizontal span | 1750mm |

| 3 | Effective cutting width | 1500mm |

| 4 | Longitudinal span | 3600mm |

| 5 | Effective cutting length | 3030mm |

| 6 | Plasma cutting power source | Huayuan LGK120A |

| 7 | Height of cutting torch | 0-150mm |

| 8 | Cutting speed | 0-15000mm/min |

| 9 | THC system | Fangling F1621 |

| 10 | Control System | F2100B |

| 11 | Nesting software | STAR CAM |

| 12 | Plasma cutting thickness | 0-10mm |

| 13 | Electrical components | Zhengtai |

| 14 | Weight | 1000KG |

| 15 | Package dimensions | 3.6m*2.28m*1.7cm |

| No. | Main parts | Model specification and description | Unit | Qty |

| 1 | CNC cutting machine | Y-axis bilateral drive, tube and plate welded heavy-duty body | pcs | 1 |

| 2 | Motor | Changzhou Chuangwei 450B | set | 3 |

| 3 | Driver | Leadshine 860H | pcs | 3 |

| 4 | Grade 7 precision rack | High precision and running smoothly | M | 6 |

| 5 | 20 square linear guide | With high precision, ultra-quiet, maintenance-free, self-dust removal, etc. | M | 6 |

| 6 | Drag chain | Y axis + X axis | vice | 2 |

| 7 | Plasma lifting device | Integrated lifting structure | set | 1 |

| 8 | Nesting software | Starcam | set | 1 |

| 9 | Smoke exhaust device | High-speed axial fan | pcs | 2 |

| 10 | Package | Plastic film + wooden box | set | 1 |

| 11 | Plasma power source | Huayuan LGK63A | pcs | 1 |

The plasma cnc machine body is a fully welded square tube structure and is finished by a planer. It adopts 8mm thickness square tube, and the beam also adopts 8mm thick square tube. The tonnage is sufficient, the weight is heavy, ensure that there is no deformation in long-term use, and the machine will not shake under high-speed operation to ensure processing accuracy. 5.2 The Plasma Cnc Machine's Transmission device

The plasma cnc machine body is a fully welded square tube structure and is finished by a planer. It adopts 8mm thickness square tube, and the beam also adopts 8mm thick square tube. The tonnage is sufficient, the weight is heavy, ensure that there is no deformation in long-term use, and the machine will not shake under high-speed operation to ensure processing accuracy. 5.2 The Plasma Cnc Machine's Transmission device  The requirements for horizontal and vertical working accuracy and positioning accuracy are relatively high. The plasma cnc machine adopts bilateral high-precision gears and rack drives. Gears, racks, machining accuracy and installation accuracy are the prerequisites for ensuring the working accuracy of the host. Under the control of the CNC control system, coupled with the speed and position detection control of the optical encoder, it is easy to control the working accuracy of the machine. The machine speed control adopts the variable frequency speed regulation drive amplifier, therefore, not only has good transmission characteristics achieved in the entire speed regulation range, but also the positioning accuracy of the machine is guaranteed. The precision-machined gears and racks ensure the plasma cnc machine's longitudinal and lateral transmission accuracy. 5.3. The Plasma Cnc Machine's Safety Protection Device

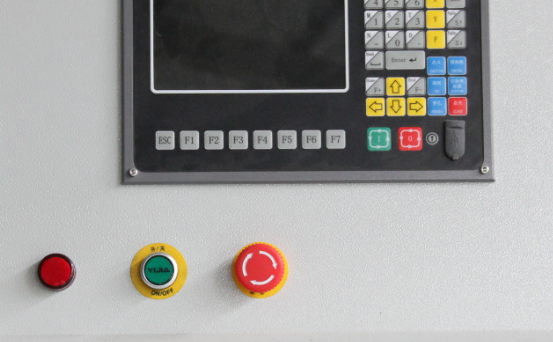

The requirements for horizontal and vertical working accuracy and positioning accuracy are relatively high. The plasma cnc machine adopts bilateral high-precision gears and rack drives. Gears, racks, machining accuracy and installation accuracy are the prerequisites for ensuring the working accuracy of the host. Under the control of the CNC control system, coupled with the speed and position detection control of the optical encoder, it is easy to control the working accuracy of the machine. The machine speed control adopts the variable frequency speed regulation drive amplifier, therefore, not only has good transmission characteristics achieved in the entire speed regulation range, but also the positioning accuracy of the machine is guaranteed. The precision-machined gears and racks ensure the plasma cnc machine's longitudinal and lateral transmission accuracy. 5.3. The Plasma Cnc Machine's Safety Protection Device  Both ends of the longitudinal guide rail and the transverse guide rail are equipped with electrical limit switches, an emergency stop switch is provided on the control cabinet, and a mechanical limit stop is provided at the same time to ensure that the anti-collision protection can also be provided when the electrical control fails. And mechanical double limit anti-collision protection. 5.4 Pneumatic Transmission Mode of the Plasma Cnc Machine

Both ends of the longitudinal guide rail and the transverse guide rail are equipped with electrical limit switches, an emergency stop switch is provided on the control cabinet, and a mechanical limit stop is provided at the same time to ensure that the anti-collision protection can also be provided when the electrical control fails. And mechanical double limit anti-collision protection. 5.4 Pneumatic Transmission Mode of the Plasma Cnc Machine  Vertical and horizontal drag chain device: a transmission mode specially designed for high-level cutting and mobile equipment. There are many working cables, grounding cables and air sources in the longitudinal direction of the plasma cnc machine that need to be introduced into the machine. Due to the large number of longitudinal cables and trachea, the longitudinal transmission load is very large, which will affect the smoothness and reliability of the plasma cnc machine. For this reason, a drag chain follow-up mechanism is adopted in the longitudinal transmission system of the plasma cnc machine to ensure the smooth running of the machine with heavy longitudinal loads. All trachea and cables are transported through drag chains, which ensures the cleanliness of the pipeline and reduces the tendency of the plasma cnc machine to overshoot when turning at high speeds. At the same time, it can effectively prevent the wear of the pipeline caused by the high-speed cutting and walking during the cutting movement, and at the same time, it can save unnecessary pipeline length. 5.5 The Plasma Cnc Machine's Rail

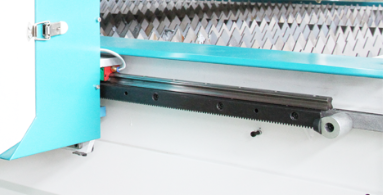

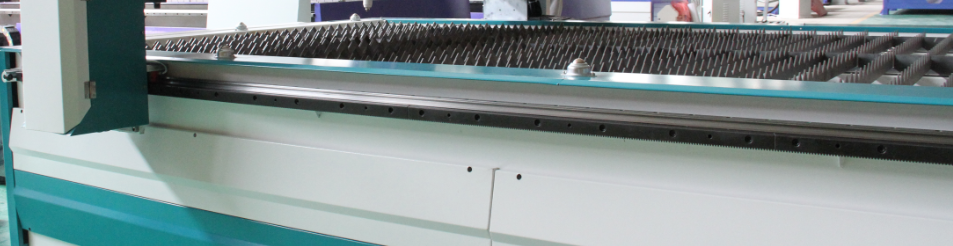

Vertical and horizontal drag chain device: a transmission mode specially designed for high-level cutting and mobile equipment. There are many working cables, grounding cables and air sources in the longitudinal direction of the plasma cnc machine that need to be introduced into the machine. Due to the large number of longitudinal cables and trachea, the longitudinal transmission load is very large, which will affect the smoothness and reliability of the plasma cnc machine. For this reason, a drag chain follow-up mechanism is adopted in the longitudinal transmission system of the plasma cnc machine to ensure the smooth running of the machine with heavy longitudinal loads. All trachea and cables are transported through drag chains, which ensures the cleanliness of the pipeline and reduces the tendency of the plasma cnc machine to overshoot when turning at high speeds. At the same time, it can effectively prevent the wear of the pipeline caused by the high-speed cutting and walking during the cutting movement, and at the same time, it can save unnecessary pipeline length. 5.5 The Plasma Cnc Machine's Rail  20 square linear guide rails are used, and the top surface and both sides are precisely processed by a special grinder. A heat-treated load rack is installed on the outer side of the guide rail. Ensure the high precision and long life of the transmission, and ensure the high precision and stability of the plasma cnc machine during the whole working period. Since the distance traveled by the CP gear per revolution is an integer, this can greatly reduce the cumulative error of the plasma cnc machine, especially for the machine with a long guide rail, its advantages are more prominent. 6. The Plasma Cnc Machine's Controller System

20 square linear guide rails are used, and the top surface and both sides are precisely processed by a special grinder. A heat-treated load rack is installed on the outer side of the guide rail. Ensure the high precision and long life of the transmission, and ensure the high precision and stability of the plasma cnc machine during the whole working period. Since the distance traveled by the CP gear per revolution is an integer, this can greatly reduce the cumulative error of the plasma cnc machine, especially for the machine with a long guide rail, its advantages are more prominent. 6. The Plasma Cnc Machine's Controller System  At present, most of the electrical cabinets used by domestic manufacturers are integrated, and the installation space is small. Stepping will produce a lot of interference waves during work, and long-term interference will bring great sequelae to the system. Such as: problems such as lost steps and crashes caused by blocked rotors. Although most of the peers have adopted the grounding method, plasma power interference still exists. The split-type design of our company is completely different from the one-piece design. The original electrical cabinet is divided into three parts: stepping, circuit, and system. Not only are all grounded, but also imported shielded wires are used on the system side. Minimize the interference and extend the life of the system to the greatest extent. The control components in the electronic control system are selected from Zhengtai electrical products, and the design of the electronic control system is safe, stable and reliable. The selected components have obvious safety marks and are products that have passed the compulsory certification of the national certification agency. 7. The Plasma Cnc Machine's CNC Controller Shanghai Fangling F2100B system is an advanced CNC Controller for flame, plasma, high-pressure water jet, and laser cutting machine developed by Shanghai Jiaotong University for our company. The interface design, cutting speed and motion control of this system are combined with advanced technology at domestic and abroad, the process performance is comprehensive, the operation is convenient, and it is a certain intelligent system in the cutting process.

At present, most of the electrical cabinets used by domestic manufacturers are integrated, and the installation space is small. Stepping will produce a lot of interference waves during work, and long-term interference will bring great sequelae to the system. Such as: problems such as lost steps and crashes caused by blocked rotors. Although most of the peers have adopted the grounding method, plasma power interference still exists. The split-type design of our company is completely different from the one-piece design. The original electrical cabinet is divided into three parts: stepping, circuit, and system. Not only are all grounded, but also imported shielded wires are used on the system side. Minimize the interference and extend the life of the system to the greatest extent. The control components in the electronic control system are selected from Zhengtai electrical products, and the design of the electronic control system is safe, stable and reliable. The selected components have obvious safety marks and are products that have passed the compulsory certification of the national certification agency. 7. The Plasma Cnc Machine's CNC Controller Shanghai Fangling F2100B system is an advanced CNC Controller for flame, plasma, high-pressure water jet, and laser cutting machine developed by Shanghai Jiaotong University for our company. The interface design, cutting speed and motion control of this system are combined with advanced technology at domestic and abroad, the process performance is comprehensive, the operation is convenient, and it is a certain intelligent system in the cutting process.  1)The system has a highly reliable design and has the ability to resist plasma interference, lightning strikes, and surges. 2)Practical flame/plasma cutting process, during plasma processing, the corner speed control and height controller control are automatically completed; 3)It has a slit compensation function, and detects whether the compensation in the program is reasonable, and makes a corresponding report for the user to choose; 4)Break point recovery, automatic power-off recovery function, automatic memory of breakpoints; 5)Arbitrary segment selection and perforation point processing function; 6) It has the function of epitaxial perforation suitable for thick plates and the bridging function suitable for thin plates; 7)Rewind, segment selection, break point recovery, optional punching position and other functions, which greatly facilitates the user's manipulation; 8)Can transfer cutting at any time; 9) Adopting special small line segment processing function, smoothly walking, can be widely used in metal blanking and advertising, iron art, etc.; 10)Part library with 24 graphics (expandable and customizable), including commonly used basic machining parts; 11) Fully compatible with various nesting software, such as: IBE (Germany), STARCAM, FASTCAM, etc.; 12)Chinese and English operation interface conversion, dynamic graphic display, 1 to 8 times graphic magnification, automatic tracking of moving points, using U disk to read programs and timely software upgrades. Technical index 1) Processor: Industrial-grade ARM7 processing chip is adopted; 2) Display: 7-inch color LCD display; 3) InputOutput: The system provides 13 channels of photoelectric isolation input and 8 channels of photoelectric isolation output; 4) Number of linkage axis: 2 axis, which can be expanded to 4 linkage axis; 5) Maximum speed: <24 m/min 6) Pulse equivalent: flexible adjustment, electronic gear numerator, denominator (1~65535) optional; 7) Storage space: 32M~64M large user program storage capacity, processing program is not restricted; 8) Chassis size: 298×202×95.2 (mm); 9) Working temperature: 0℃~ +40℃; storage temperature: -40℃ ~ +60℃; 8. Motor Drive of the Plasma Cnc Machine

1)The system has a highly reliable design and has the ability to resist plasma interference, lightning strikes, and surges. 2)Practical flame/plasma cutting process, during plasma processing, the corner speed control and height controller control are automatically completed; 3)It has a slit compensation function, and detects whether the compensation in the program is reasonable, and makes a corresponding report for the user to choose; 4)Break point recovery, automatic power-off recovery function, automatic memory of breakpoints; 5)Arbitrary segment selection and perforation point processing function; 6) It has the function of epitaxial perforation suitable for thick plates and the bridging function suitable for thin plates; 7)Rewind, segment selection, break point recovery, optional punching position and other functions, which greatly facilitates the user's manipulation; 8)Can transfer cutting at any time; 9) Adopting special small line segment processing function, smoothly walking, can be widely used in metal blanking and advertising, iron art, etc.; 10)Part library with 24 graphics (expandable and customizable), including commonly used basic machining parts; 11) Fully compatible with various nesting software, such as: IBE (Germany), STARCAM, FASTCAM, etc.; 12)Chinese and English operation interface conversion, dynamic graphic display, 1 to 8 times graphic magnification, automatic tracking of moving points, using U disk to read programs and timely software upgrades. Technical index 1) Processor: Industrial-grade ARM7 processing chip is adopted; 2) Display: 7-inch color LCD display; 3) InputOutput: The system provides 13 channels of photoelectric isolation input and 8 channels of photoelectric isolation output; 4) Number of linkage axis: 2 axis, which can be expanded to 4 linkage axis; 5) Maximum speed: <24 m/min 6) Pulse equivalent: flexible adjustment, electronic gear numerator, denominator (1~65535) optional; 7) Storage space: 32M~64M large user program storage capacity, processing program is not restricted; 8) Chassis size: 298×202×95.2 (mm); 9) Working temperature: 0℃~ +40℃; storage temperature: -40℃ ~ +60℃; 8. Motor Drive of the Plasma Cnc Machine  Chuang wei motor driver function General operating modes: position, speed, torque 8 sets of built-in motion tasks (position control) Automatic motor recognition Gain automatic adjustment Resonance suppression Command smoothing and low-pass filtering Advantage Complete product series Rich control functions Intelligent software Easy to use 9. Automatic Programming Nesting Software of The Plasma Cnc Machine

Chuang wei motor driver function General operating modes: position, speed, torque 8 sets of built-in motion tasks (position control) Automatic motor recognition Gain automatic adjustment Resonance suppression Command smoothing and low-pass filtering Advantage Complete product series Rich control functions Intelligent software Easy to use 9. Automatic Programming Nesting Software of The Plasma Cnc Machine  The development of STAR CAM CNC cut is to meet the requirements of the enterprise: it has many functions and is easy to operate. This software is suitable for various cutting methods, such as: water jet cutting, flame cutting, plasma cutting and laser cutting, etc., no need to load other cutting methods more software. Customers do not need to have basic knowledge, and can easily load DXF graphics into the software. Or use our integrated CAD-system STAR CAM Cad to create graphics. Process data will be automatically generated through CNC cut graphics. The software will also provide the best processing path, and this processing path can be changed at any time as required. The graphics converted into CAM mode are directly generated, and there is no need to convert back and forth in different user interfaces. Only a few mouse clicks can get a complete nesting diagram. Then click again to generate the NC program! We provide three nesting methods. The simplest way is to nest in the form of a grid. As its name says, all parts will be nested in a square grid, and then nested on the board. This nesting method is the simplest. Nesting in the form of a grid can only nest one type of parts in batches at the same time. The same is true for nesting. This nesting method is exclusively provided by our company. Its characteristic is that a single part can be compactly and optimally sleeved on the plate, thereby effectively improving the utilization rate of the plate. There is also a nesting method that is arranged in the correct shape, and multiple parts of different types can be nested at the same time. Therefore, the correct shape is often referred to as multiple parts nesting at the same time. All nesting methods have one thing in common, that is, the operation is fast and simple. Cnc CUT not only provides common functions, but is also equipped with unique functions such as common edge manual automatic interactive nesting drawing, which effectively improves nesting efficiency, metal sheet utilization, and saves processing time. 10. The Plasma Cnc Machine's THC Shanghai Fangling F1621

The development of STAR CAM CNC cut is to meet the requirements of the enterprise: it has many functions and is easy to operate. This software is suitable for various cutting methods, such as: water jet cutting, flame cutting, plasma cutting and laser cutting, etc., no need to load other cutting methods more software. Customers do not need to have basic knowledge, and can easily load DXF graphics into the software. Or use our integrated CAD-system STAR CAM Cad to create graphics. Process data will be automatically generated through CNC cut graphics. The software will also provide the best processing path, and this processing path can be changed at any time as required. The graphics converted into CAM mode are directly generated, and there is no need to convert back and forth in different user interfaces. Only a few mouse clicks can get a complete nesting diagram. Then click again to generate the NC program! We provide three nesting methods. The simplest way is to nest in the form of a grid. As its name says, all parts will be nested in a square grid, and then nested on the board. This nesting method is the simplest. Nesting in the form of a grid can only nest one type of parts in batches at the same time. The same is true for nesting. This nesting method is exclusively provided by our company. Its characteristic is that a single part can be compactly and optimally sleeved on the plate, thereby effectively improving the utilization rate of the plate. There is also a nesting method that is arranged in the correct shape, and multiple parts of different types can be nested at the same time. Therefore, the correct shape is often referred to as multiple parts nesting at the same time. All nesting methods have one thing in common, that is, the operation is fast and simple. Cnc CUT not only provides common functions, but is also equipped with unique functions such as common edge manual automatic interactive nesting drawing, which effectively improves nesting efficiency, metal sheet utilization, and saves processing time. 10. The Plasma Cnc Machine's THC Shanghai Fangling F1621  1) New operation panel design and color matching, upgrade the grade; optimize the follow algorithm to improve the cutting quality 2) Push-down knob, clean and simple, easy to operate 3) Using high-power arc starting relay to enhance the stability of arc starting 4) Double LED digital display, simple and clear 5) Newly added dynamic perforation knob, convenient for real-time change of parameters, to achieve better cutting effect 11.Cutting Sample

1) New operation panel design and color matching, upgrade the grade; optimize the follow algorithm to improve the cutting quality 2) Push-down knob, clean and simple, easy to operate 3) Using high-power arc starting relay to enhance the stability of arc starting 4) Double LED digital display, simple and clear 5) Newly added dynamic perforation knob, convenient for real-time change of parameters, to achieve better cutting effect 11.Cutting Sample  12.Customer Use Case for The Plasma Cnc Machine

12.Customer Use Case for The Plasma Cnc Machine